-

Intensive three phase HP washers

-

Intensive Petrol hot water HP washers

-

Semi-professionnal single phase HP washers

-

Mono professional hot water HP washers

-

Professional three phase hot water HP washers

DIMACO

Choose your HP washers l Choose your nozzle l Technical advice l Maintenance advice

Technical advice

___________________________________________________________________________________________

|

|

|

______________________________________________________________________________________________________________________________________________________________________________________________________

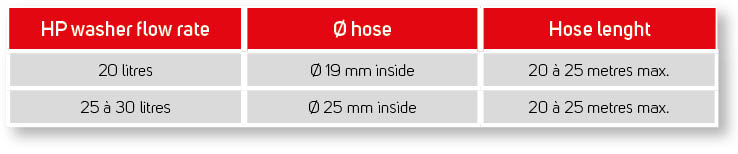

Real flow rate of the water networkTo get a flow rate of 20 l/min, i.e. 1 200 l/h, your water network flow rate needs to be 20 to 30 % higher than 20 l/mn. Diameter of the water inlet hose (low pressure) : Usable amperage of the electric network : ground fault circuit interrupter

Use of an extension cable : always completely uncoil the cable

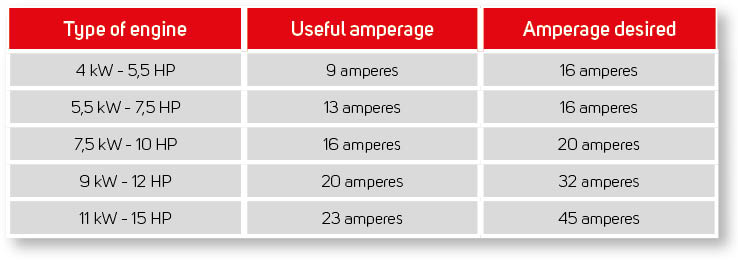

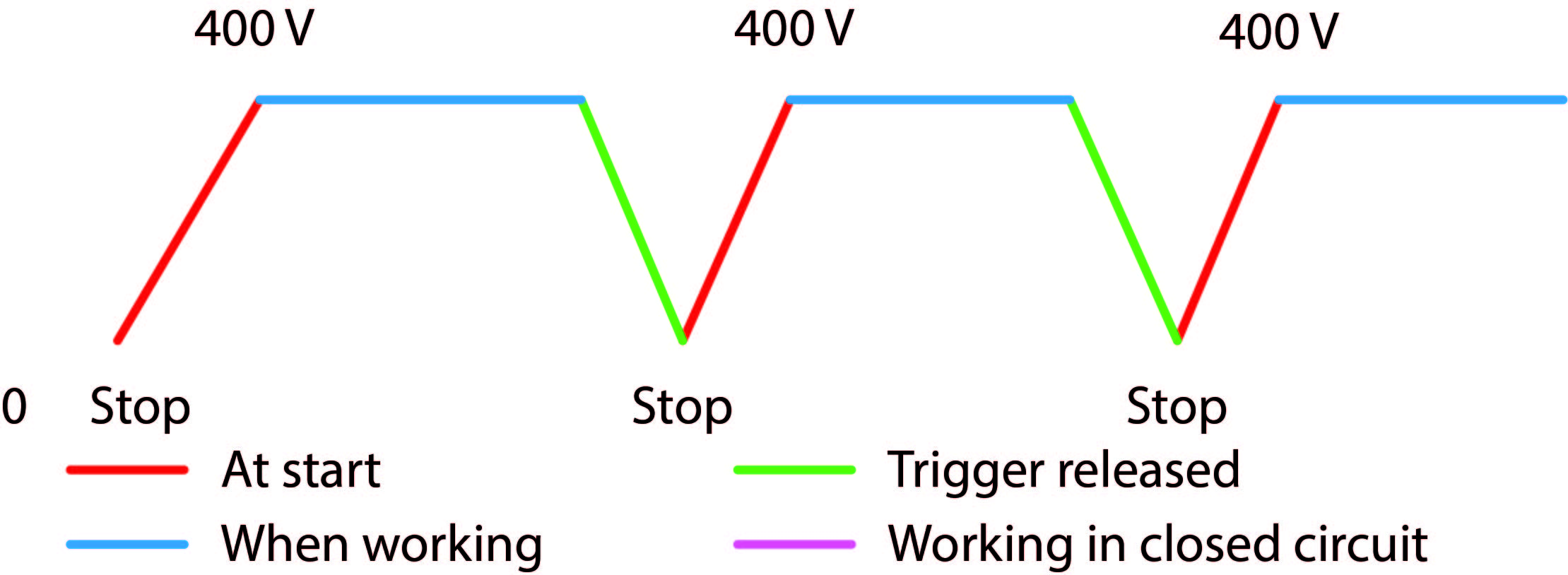

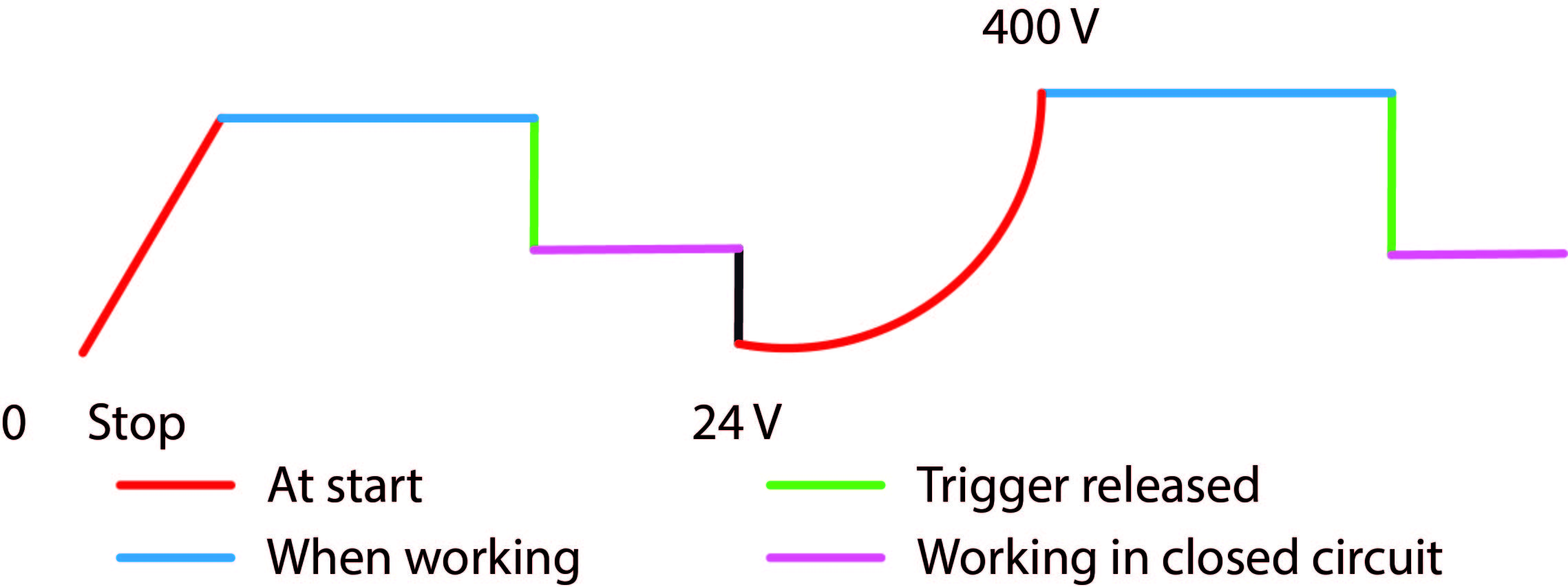

Temperature of the HP washer according to its useAfter releasing the trigger of the HP washer, the water temperature increases quickly, which can lead to overheating of the pump.

|

|

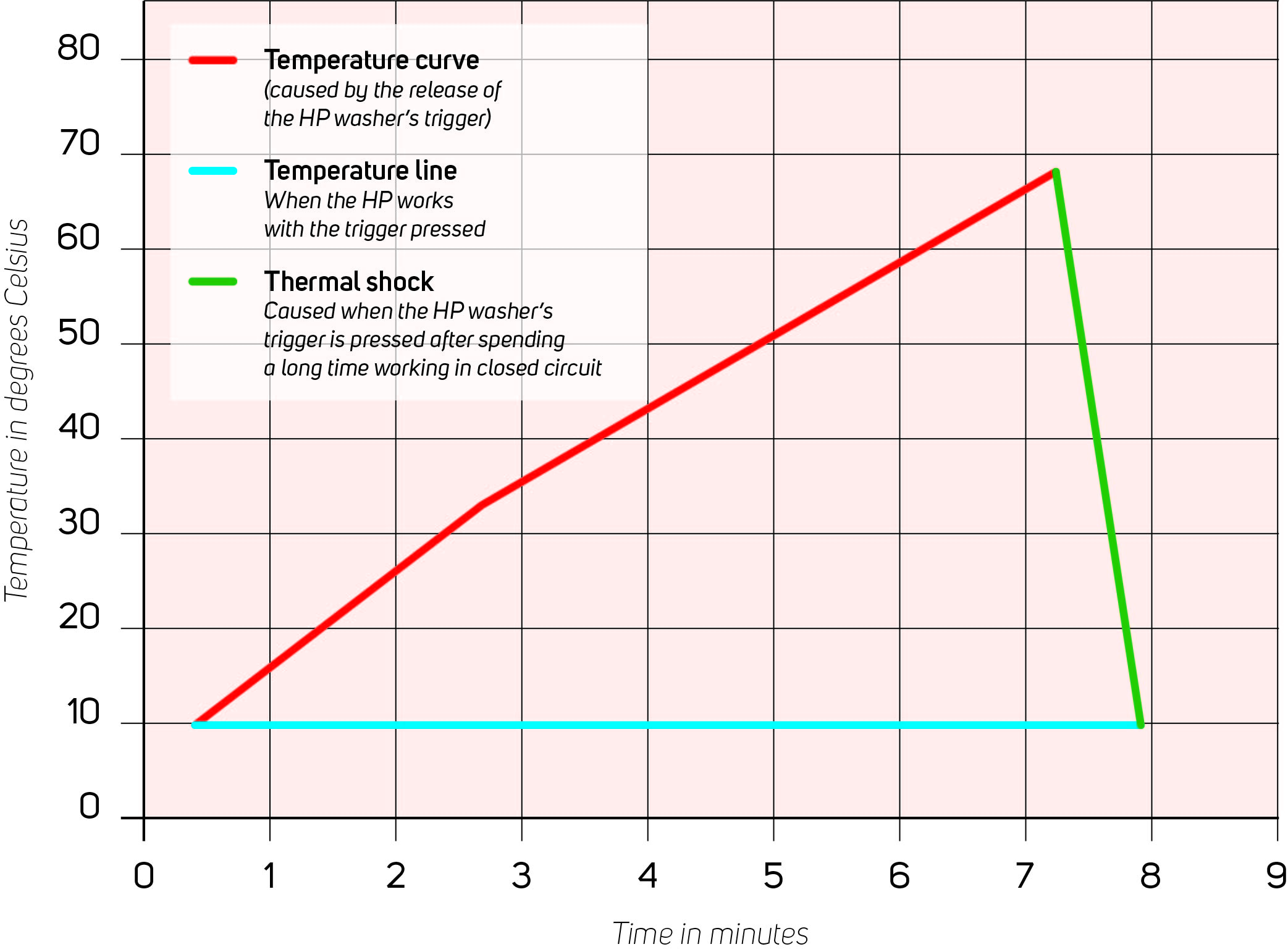

Never leave the HP washer work in closed circuit during more than 2 minutes. Various solutions to avoid overheating : Return to buffer tankAfter releasing the trigger of the HP spray gun, the regulator sends the water back in the buffer tank.

Total stop (Automatic Start/Stop)After releasing the trigger of the HP spray gun, the engine stops.

Time delayed automatic Start/StopAfter releasing the trigger of the spray gun, the engine continues to work during the time set, then stops. This avoids too many starts.

|

|

It works on the principle of the internal combustion engine with a crankshaft, connecting rods and pistons (2, 3 or 6), in an oil sump : a simple tried and tested concept, easy to maintain (first oil change after 50 hours, then every 250 hours) and repair (all parts are fully accessible).

|